|

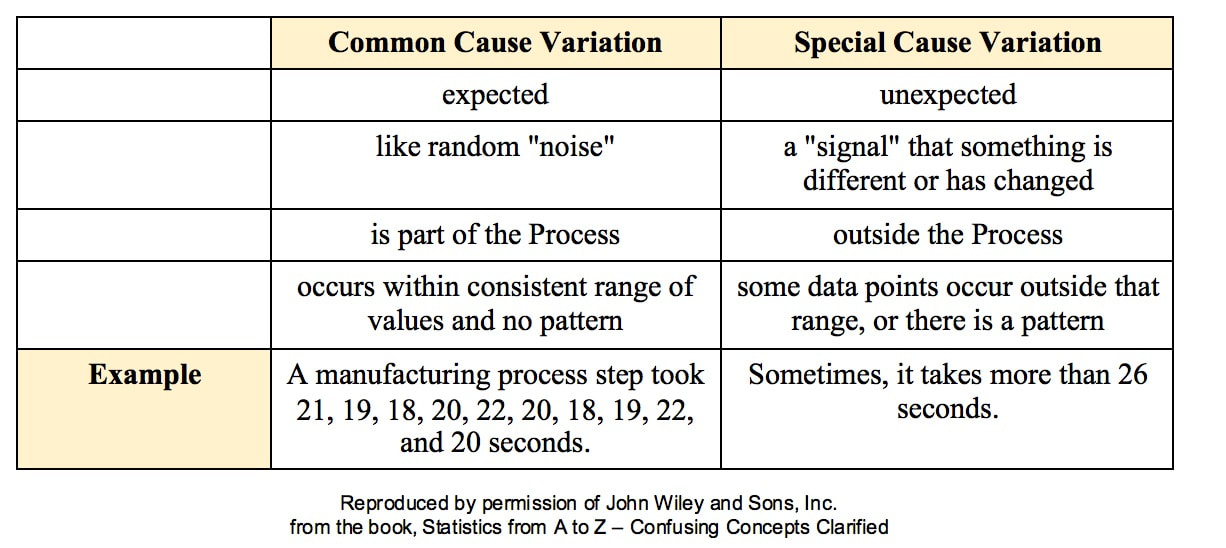

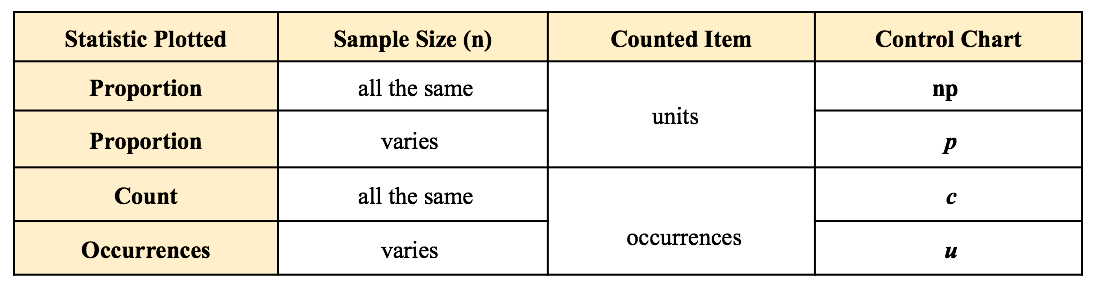

My blog post of April 6, 2017 discussed how Control Charts and Run Rules are used to distinguish Common Cause from Special Cause Variation. Common Cause Variation is the usual, expected, random "noise" variation that all processes have. It occurs within limits and it exhibits no pattern. If all we have is Common Cause Variation, then we can begin implementing process improvement techniques to reduce this variation. But if the variation exceeds the limits in a Control Chart or if it exhibits patterns described in Run Rules, then the process in not in control. Special Cause Variation is in effect, and that needs to be addressed first. There are a number of different types of Control Charts. For Discrete/ Count data (integers) here are the Control Charts to use. What's the difference between units and occurrences? Let's say we are inspecting shirts that we are manufacturing. One shirt with 3 defects would count as 1 defective unit or 3 occurrences of defects.

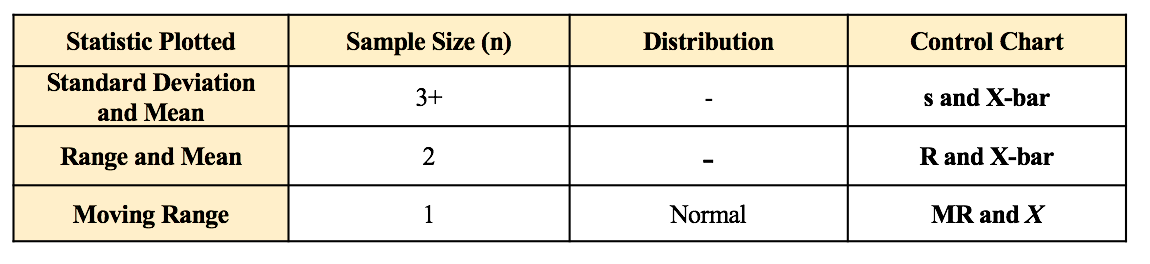

For Continuous/ Measurement data (real numbers), use the following charts:

0 Comments

Leave a Reply. |

AuthorAndrew A. (Andy) Jawlik is the author of the book, Statistics from A to Z -- Confusing Concepts Clarified, published by Wiley. Archives

March 2021

Categories |

RSS Feed

RSS Feed