|

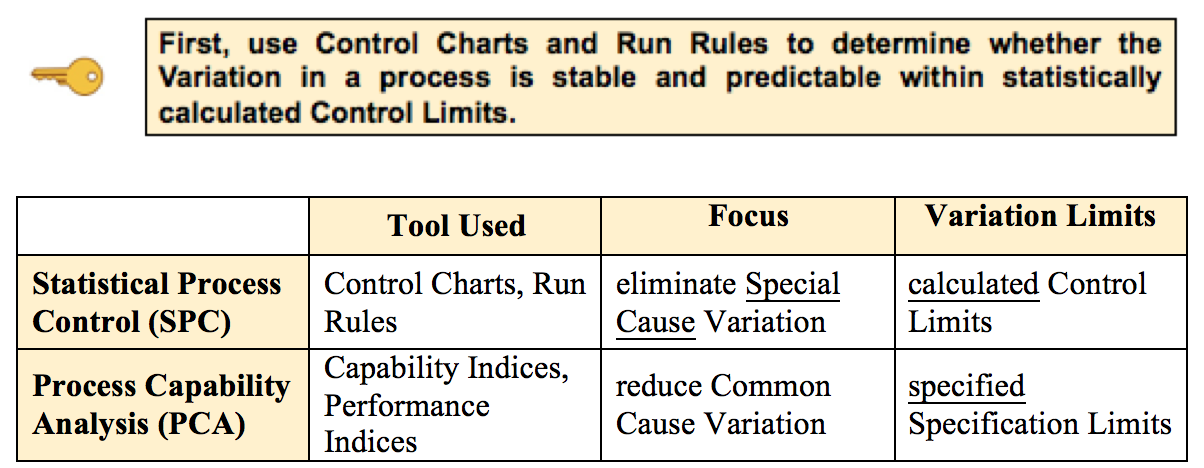

Our Statistics Tip of the Week for April 6, 2017 explained Common Cause Variation and Special Cause Variation in a process. It also explained how Control Charts and Run Rules could be used to identify Special Causes, which are extraneous causes of Variation that are outside the process. Then -- if needed -- action could be taken to eliminate the Special Causes. This analysis and action -- Statistical Process Control (SPC) -- is an important part of the Six Sigma process improvement discipline. Here is the first of 5 Keys to Understanding in the article in the book about Process Capability Analysis, which is usually the next step after Statistical Process Control. When the Special Causes have been eliminated, we can then take action to improve the process. By improving, we mean reducing Common Cause Variation. That is the Variation that is left once Special Cause Variation has been eliminated.

We measure the process's Capability and Performance before and after possible improvement actions taken, using the tools and techniques of Process Capability Analysis (PCA). More on PCA in a future Tip of the Week.

0 Comments

Leave a Reply. |

AuthorAndrew A. (Andy) Jawlik is the author of the book, Statistics from A to Z -- Confusing Concepts Clarified, published by Wiley. Archives

March 2021

Categories |

RSS Feed

RSS Feed